From Prototype to Production

For Beginners and Professionals Alike

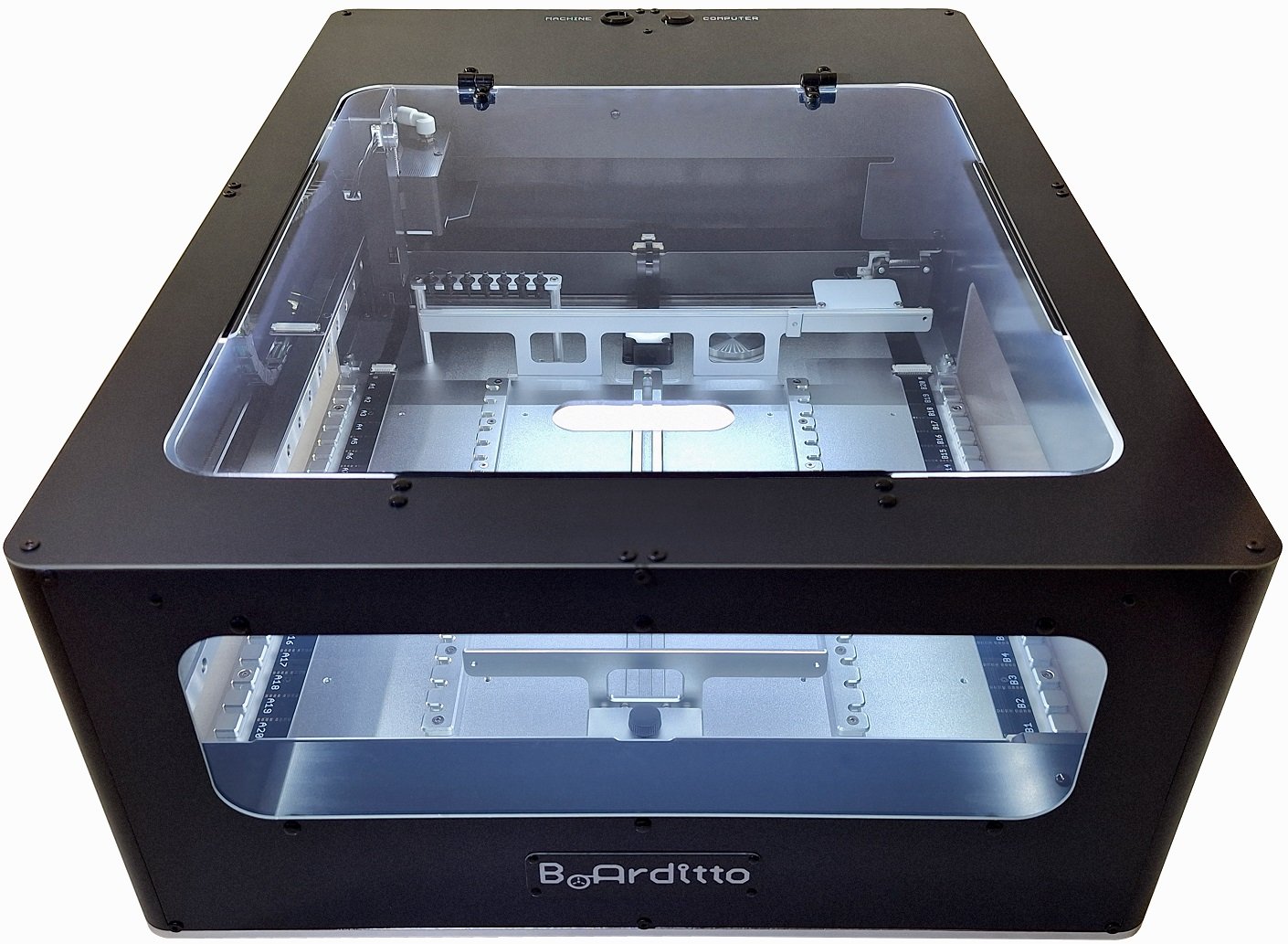

The Boarditto 2 Pro desktop pick and place machine assists you every step of the way with your PCBs, from single prototypes to mass production. You get industrial-grade accuracy, reliability, and speed all packed in a machine that is easy to use and fits on your desk.

Latest Updates

7 Mar: UPS shipping method added for the U.S.

2 Mar: Some of those who have contacted us have reported not receiving our replies to submissions sent by contact form. We've disabled the contact form until the issue has been fixed. In the meantime, please email us directly via sales@boarditto.com Please check your junk/spam folder regardless of the contact method used.

28 Feb: New guide for Choosing Feeder Combinations

20 Feb: New 0201 video released

Coming Up

New shipping methods will be added soon.

Key Features

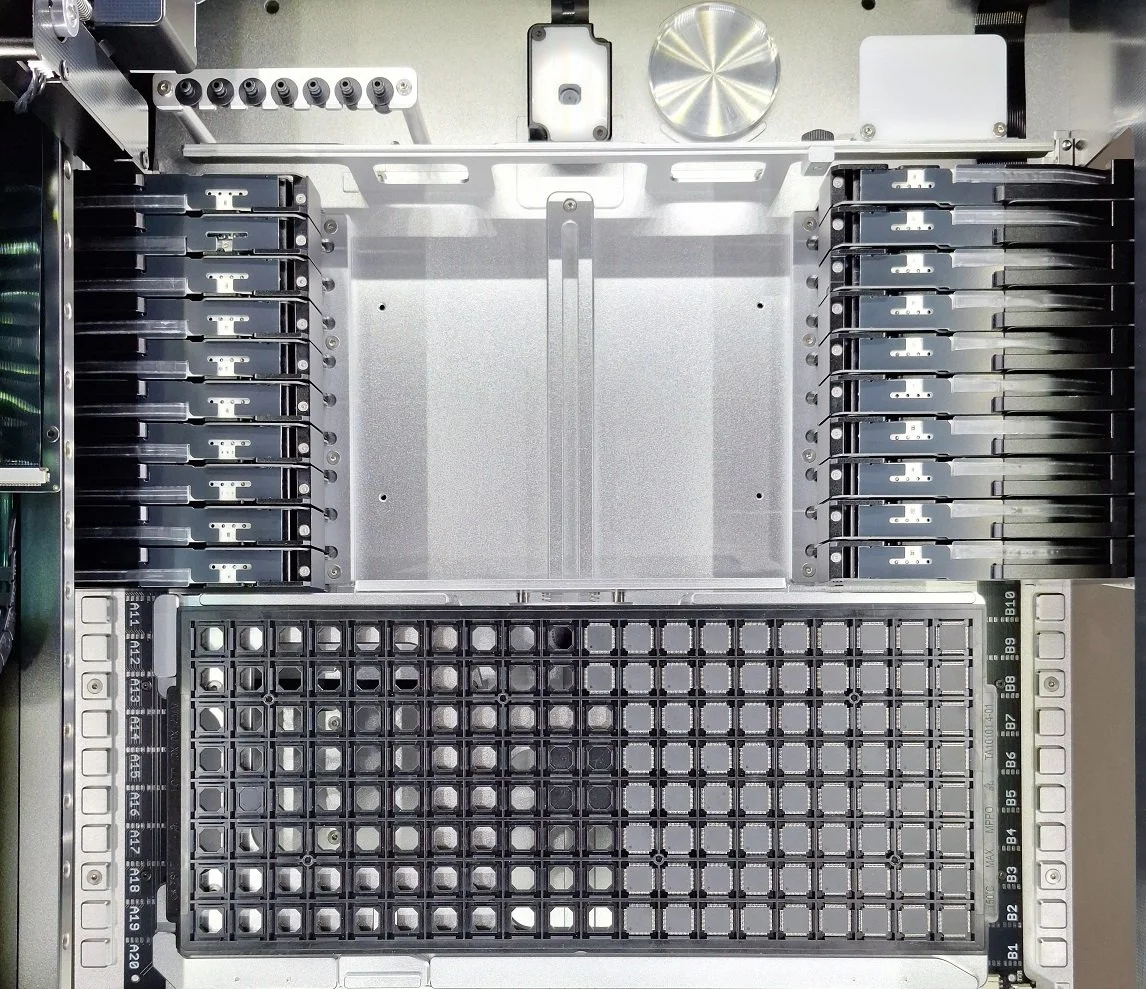

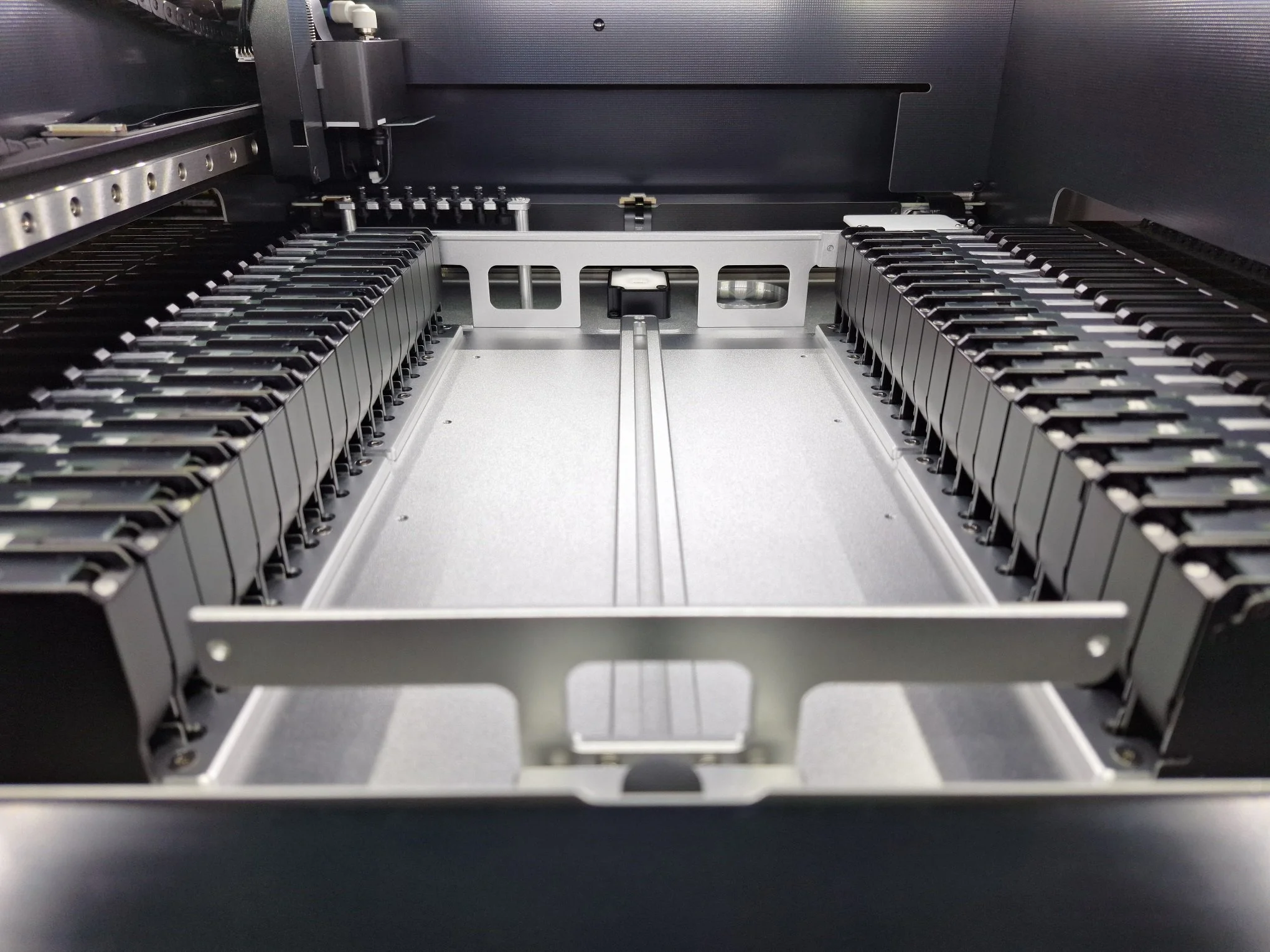

Lots of Room & Flexibility

Accepts standard JEDEC trays and supports up to 40 feeders. Feeders come in a variety of types and widths, giving you plenty of options for meeting your project's needs.

The maximum PCB working area is 324mm x 333mm (12.76in. x 13.11in.).

Basic Motion Demo - Actual Speed

High Speed Production

Delivers throughput up to 2100 CPH (Components Per Hour) with vision or up to 3800 CPH without vision.

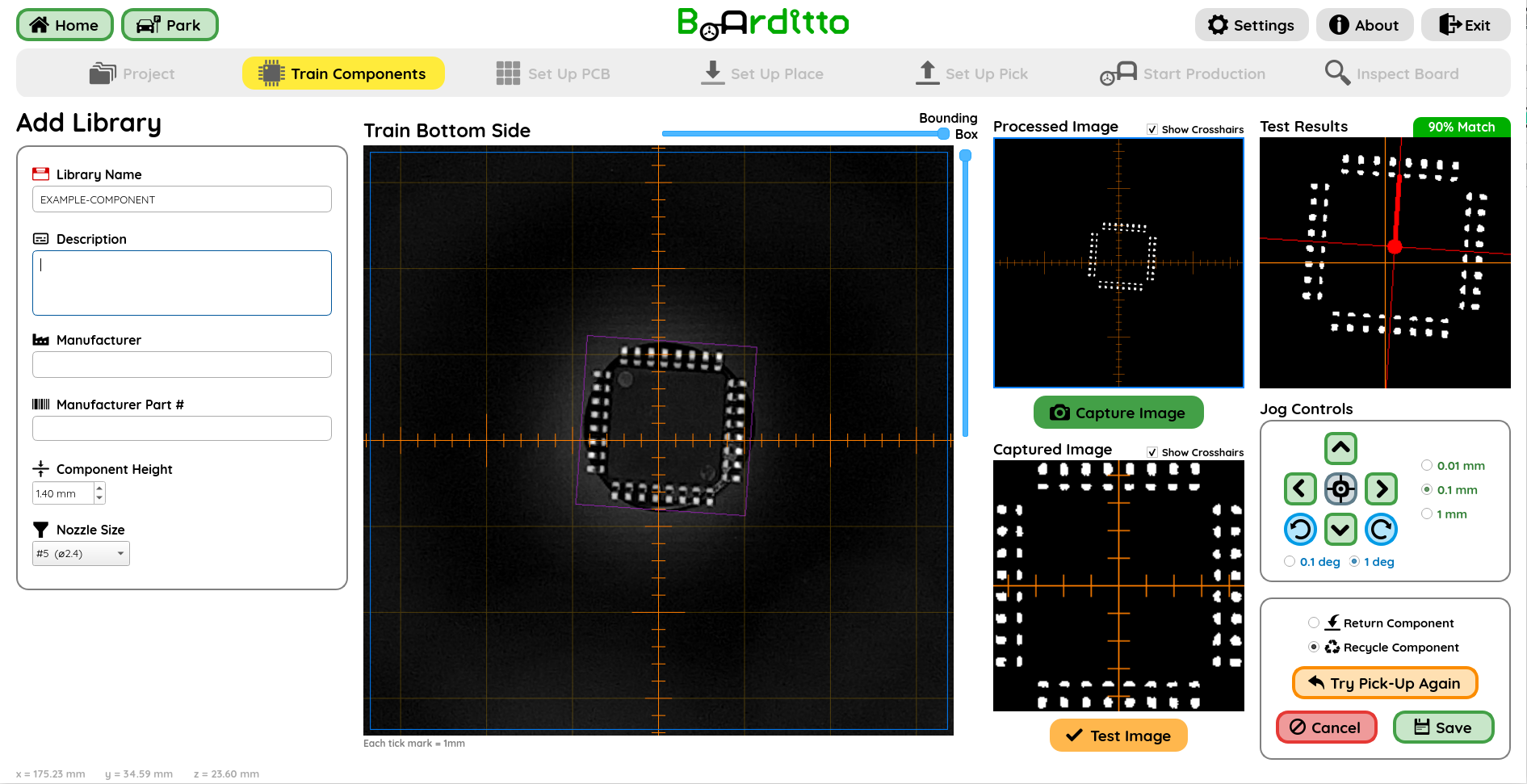

Simple Setup and Easy to Use

Factory-Calibrated for Precision: We take the guesswork out of setup. Each machine is factory-calibrated, ensuring accuracy from the moment you power it on. You can have it running in just minutes!

User-Friendly but Mighty Software: Our proprietary Boarditto Software v2 presents an intuitive user interface with a step-by-step flow that guides you all the way to achieve professionally-assembled PCBs.

All-in-One Solution: Has a built-in computer with our software pre-installed and fully configured.

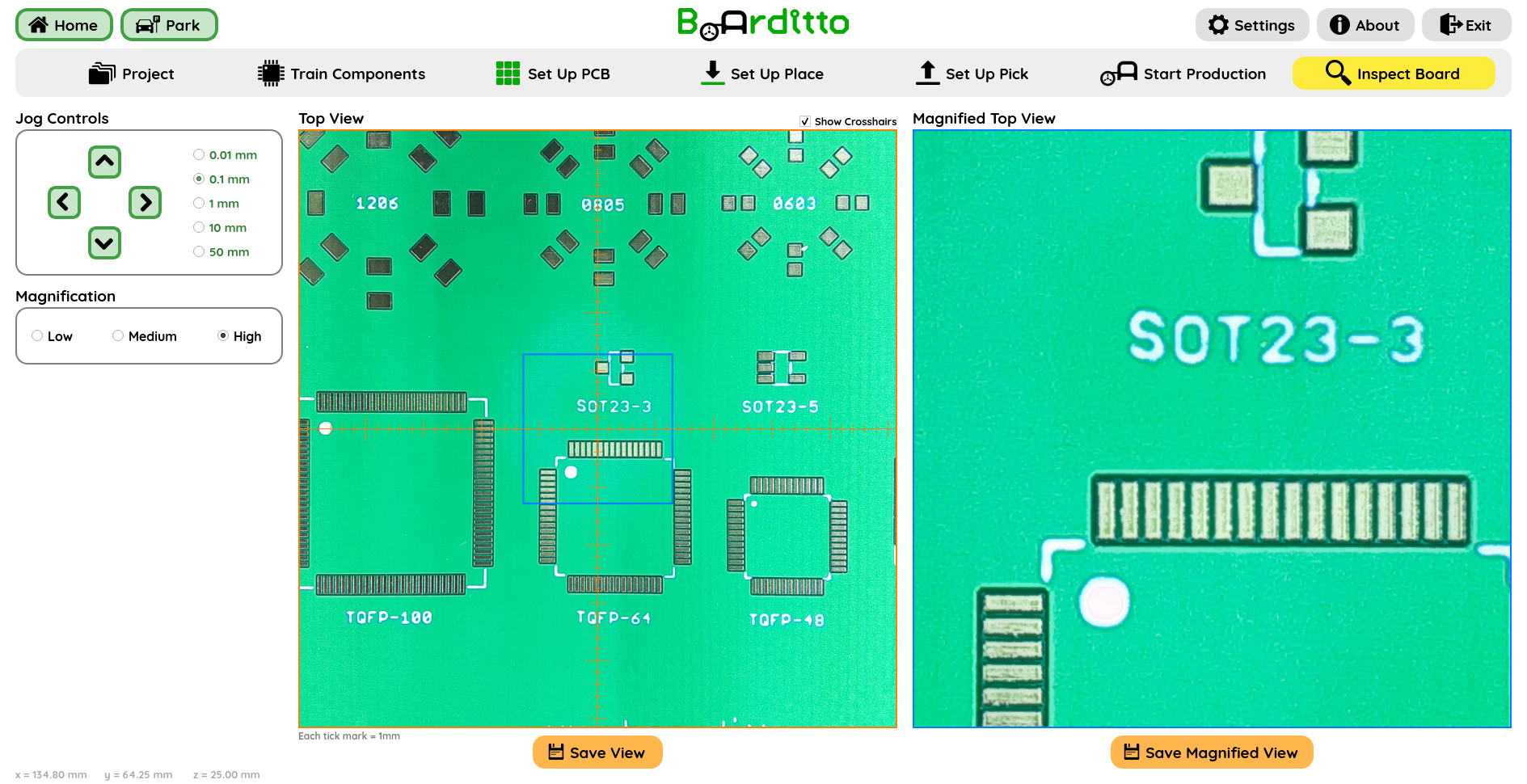

High Resolution Vision System

Two cameras with 4K square-image resolution deliver exceptional image quality of your board and components with built-in digital microscope functionality for detailed PCB and component inspection.

Precision and Reliability

Confidently assemble boards with components as small as 0201, which measures a tiny 0.3mm x 0.6mm (0.01in. x 0.02in.).

TQFP64 and JEDEC Tray - Prototyping Demo

0201 Demo: Close-up view. A 0201 component measures 0.3mm x 0.6mm (0.01in. x 0.02in.)

Solid Build Quality

All-Metal Construction: Every structural component is precision-manufactured from high-grade aluminum and stainless steel. This provides a rock-solid foundation for exceptional rigidity, accuracy, and long-term reliability, giving you confidence in your assembly process, project after project.

Dimensional Stability: Metal’s inherent stability resists warping due to temperature fluctuations or humidity changes, maintaining consistent performance and dimensional accuracy over the lifespan of the machine.

Controlled Lighting: Tinted panels combined with a fully-enclosed design and integrated LEDs create stable internal illumination, eliminating the impact of external lighting. This ensures accurate fiducial detection, consistent component training, and reliable performance regardless of room lighting conditions.

Rapid Tool Changer

Lightning-fast nozzle changes (under 1 second) keep your production flowing smoothly.

Tool Changer Demo

Designed for Your Space

Compact & Portable: At just 8.5kg (18.7 lbs) and a size of 42cm x 58cm x 20cm (16.54in. x 22.83in. x 7.87in.), this machine can be easily moved between workstations or rooms. Its efficient design provides a surprisingly large internal work area despite its small footprint, maximizing your valuable desk space.

Quiet Operation: Sound level between 45 and 58 decibels during operation (measured at 1 meter)—about the same volume as normal conversation—makes it perfect for home, classroom, or office use.

Enhanced Safety for Classroom Use: The fully-enclosed design is engineered with safety in mind, protecting curious hands and ensuring a secure learning environment for students.

Technical Specs

Download Product Datasheet

Machine Dimensions: 42cm x 58cm x 20cm (16.54in. x 22.83in. x 7.87in.)

Machine Weight: 8.5kg (18.7 lbs)

Maximum PCB Working Area: 324mm x 333mm (12.76in. x 13.11in.)

Minimum Component Size: 0201 (0.3mm x 0.6mm | 0.01in. x 0.02in.)

Minimum Chip Package Pitch: 0.2mm (0.0079in.)

Maximum Component Size: 32mm x 32mm (1.26in. x 1.26in.)

Maximum Component Height: 23mm (0.91in.)

Vision: Two cameras (top and bottom) with 4K square-image resolution

Speed: Up to 2100 CPH (Components Per Hour) with vision; up to 3800 CPH without vision

Decibel Rating: Between 45dB and 58dB during operation (measured at 1 meter away)

Feeder Capacity: Up to 40 feeders

Tray: Optional tray holder supports a full standard JEDEC tray

Tool Changer: Holds 7 different nozzle sizes

Nozzles: Includes nozzle sizes #1, #2, #3, #4, #5, #6, #7

Computer: Built-in

Software: Boarditto Software v2 pre-installed and fully configured. Can import placement data from any EDA software

Connectivity: 1x HDMI, 2x USB A

Requirements: Monitor (recommended resolution: 1920x1080 pixels), USB keyboard and mouse